Need a feasibility check?

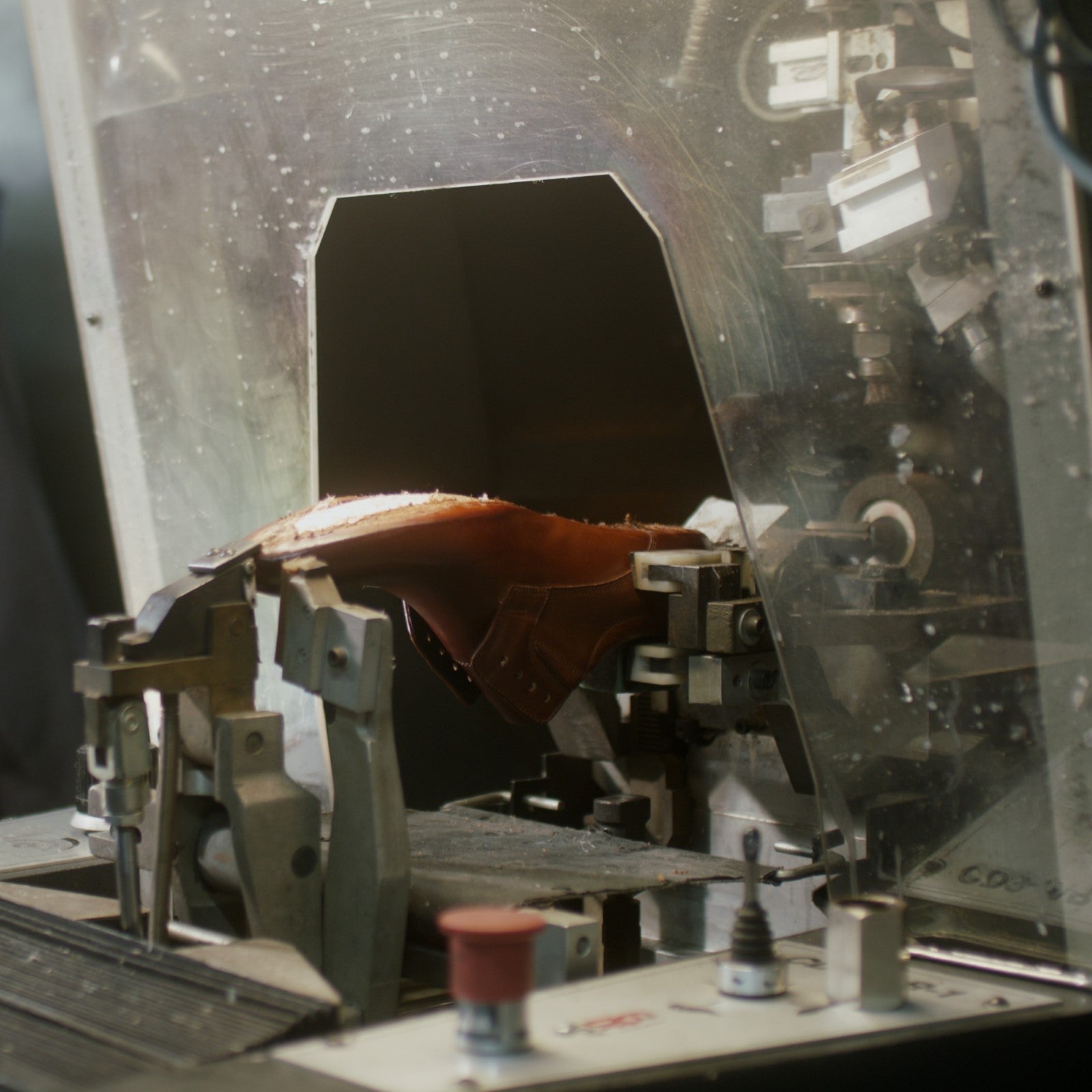

Rapid Prototyping & Development

Go from sketch to wear-test pair in 7–14 days

Built in Poland — weeks, not months.

- Complex builds welcome: waterproof, safety, 3-D knit, advanced trekking.

- Material options on tap: vegan, recycled, premium leather — you pick the story.

- Direct Teams/Zoom loop with senior pattern engineers — same-day CAD tweaks.

- IP stays in EU — files & prototypes never leave our campus.

Services

1. Pick-&-Ship Catalog

5 000+ proven styles ready to go. Ship a market-test batch in 2-3 weeks — no design work, no tooling, MOQ 100 pairs. Use our TAPI branding or white-label for a small surcharge.

2. Quick Branding

Select any catalog model and make it yours: swap leathers/colours, add logo stamps, custom box & hang-tags. One-time tooling from € 500. Wear-test sample in 7–14 days, pilot 10 pairs, bulk in 1-4 weeks.

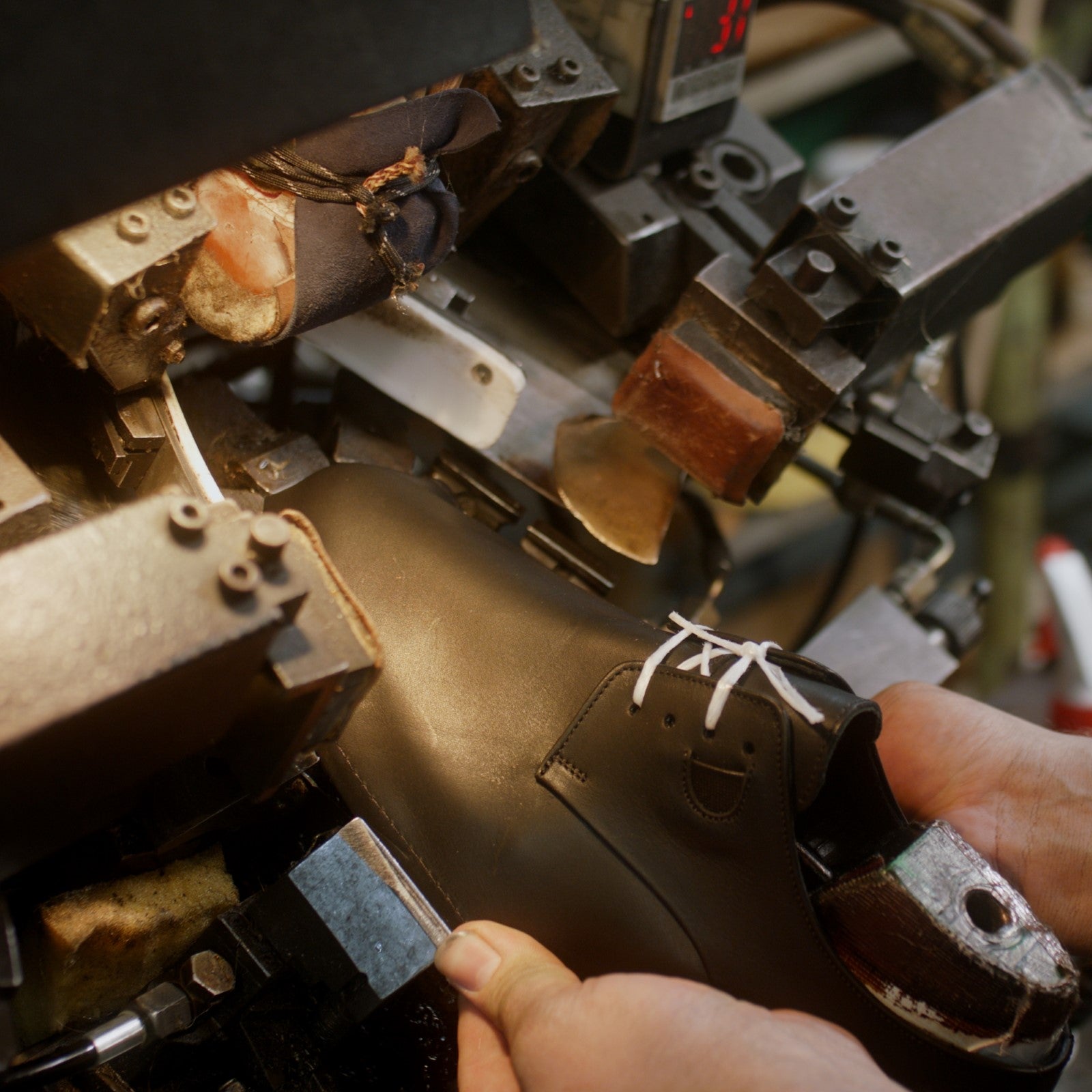

3. New Upper on Existing Tooling

Send a sketch or tech pack; we match it to our 400+ lasts and outsoles. No outsole mould cost. Waterproof, sneakers, 3-D knit — anything the project needs. Prototype 7–14 days, pilot 10 pairs, bulk in 4–6 weeks.

4. Ground-Up Platform

Need an exclusive last, outsole or totally new concept? Our team handles lasts design, moulds and fit validation. Typical timeline 12–20 weeks inc. mould build; capacity scales to 10 000 + pairs / month.

Flexible & Scalable Production

EU Production That Scales With You — Fast, Flexible, Proven.

Cut transit time, cut MOQs — produce where your market is.

Custom Finishing

Hand-paint, aerograph, special effects in-house, MOQ 100 to develop new colour.

Get a Quote

NICHE-READY CAPABILITIES — POWERED BY SMART TECH

MEET THE OUTLIER REQUIREMENTS YOUR CURRENT FACTORY CAN’T TOUCH.

From EU toddler size 18 to plus-size 51—and from certified vegan textiles to mil-spec safety boots—our smart-tech lines turn niche demands into commercially viable runs.

- Extreme sizing — EU 18–51 on the same line, no new tooling.

- Smart tech — 3-D knit + IIoT keep claims < 0.1 %.

- Certified vegan — V-Label materials hit eco targets fast.

- Mil-spec flow — ISO 9001 + AQAP 2110 ready for tenders.