6 000 prs / month

Month-level capacity under one roof in Poland. Proven peak: 10 900 prs/mo (Q4 2019).

Scalable to 10 000 pairs in a quarter

Ramp to 10 000 within 12 weeks – same team, same roof

MOQ 1 pair

Test the market fast; iterate without Asia lead-times.

< 0.1 % claim rate

Audited Mar 2025 – only 0.096 % returns last 12 months

Capabilities Engineered for Your Competitive Edge

Rapid, Complex Prototyping

Turn ambitious concepts into tangible samples in just 7-14 days.

We specialize in technically demanding designs – waterproof, safety, trekking, 3D knit, and more. Leverage our deep engineering know-how.

Flexible EU Production

De-risk your launch with low MOQs .

Our agile Jordanów, Poland facility enables Just-in-Time delivery and rapid response to market needs.

Discover Production Flexibility

Advanced Technology Integration

Access cutting-edge manufacturing:

3D knitting (Santoni), robotics (Universal Robots), precision cutting (Zund), 8 assembly systems, and ongoing R&D (3D printing).

Solve challenges with the right tech.

See Our TechnologyProof you can touch

All figures come from Tapi’s in-house MES and can be audited on-site during factory visit or factory live tour (via Teams/Zoom) under NDA.

13 800 pairs

Largest single model order (1 model in 1 colour) a top 10 biggest specialized shoe retailer in Europe. 1000+ stores.

9 290 / yr pairs

Loyal client since 2014. Average yearly order across ~70 model/colour combination per year. 100+ stores.

200+ retailers

Tapi own label. Men’s dress shoes, sneakers and waterproof trekking shoes. 70% made to order. 1-10 stores.

15-30 SKUs / week

Mass-customization program with innovative startup. Weekly cycle

manufactured on demand. Online store.

Technology Spotlight

Innovation Woven In: Seamless 3D Knitting

Leverage our Santoni 3D knitting capabilities for revolutionary, seamless uppers. Reduce waste, enhance comfort, and create unique aesthetics for sneakers and specialized footwear. We help integrate this tech effectively.

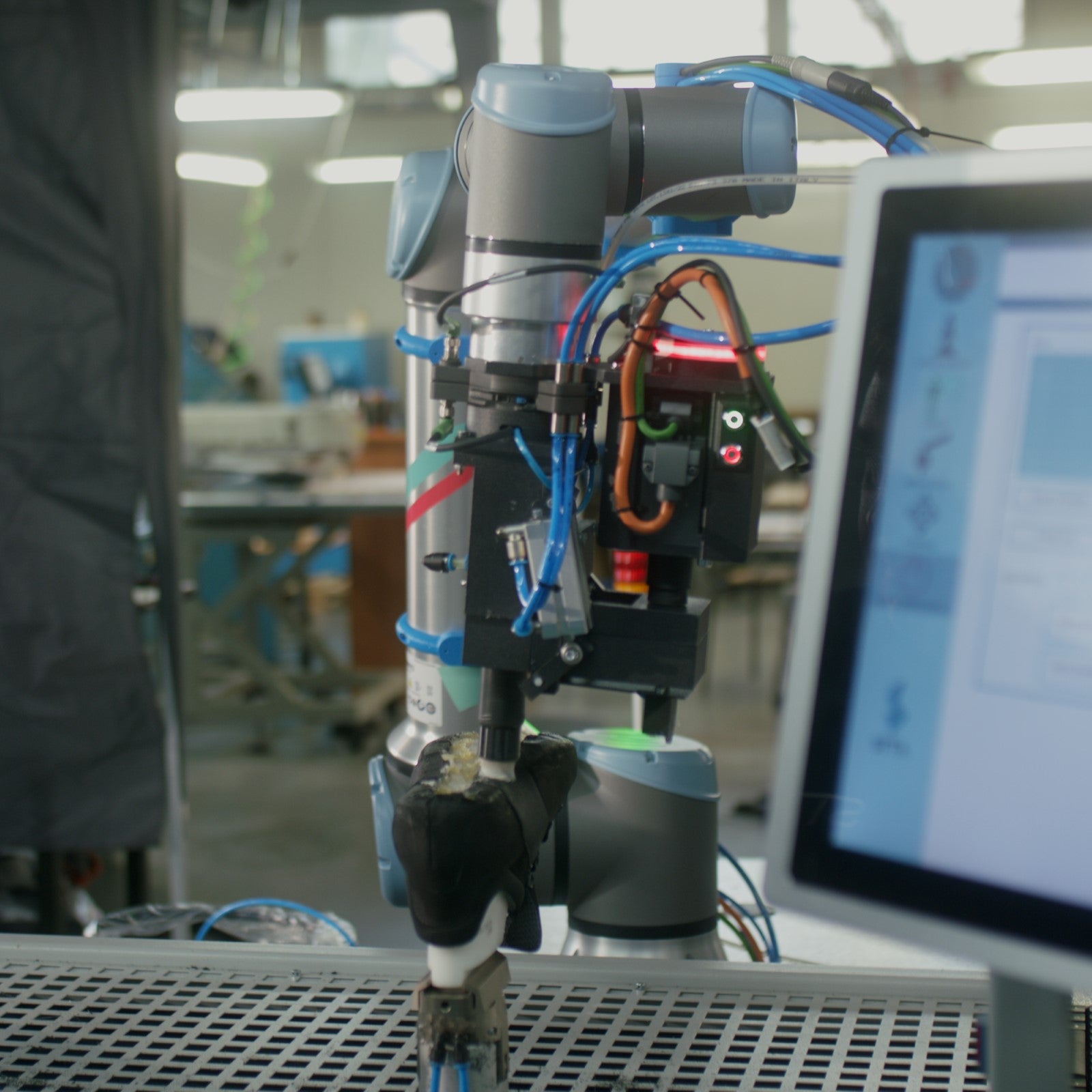

Precision & Consistency: Collaborative Robotics

Our Universal Robots Cobot integration enhances precision in repetitive tasks like gluing and buffing. This boosts quality control, production efficiency, and enables consistent results for complex assemblies.

Why Partner With Tapi?

Your Strategic Advantages

Strategic EU Production

Benefit from quality control, IP protection, stable lead times, and seamless communication with our wholly-owned Polish facility.

Unmatched Flexibility

Launch faster and reduce risk with MOQs from 1 pair and rapid prototyping (7-14 days). Adapt quickly to market demands.

Proven Technical Expertise

Over 70 years of footwear engineering across 3 generations, tackling complex constructions daily. ISO 9001 & AQAP 2110 certified.

Responsible Manufacturing

Committed to sustainability. Verified >50% CO2 reduction, focus on local supply chains, waste reduction, and exploring eco-materials (incl. vegan).

See Where Innovation Happens: Visit Our factory

We believe in transparency. Schedule a visit to our Jordanów facility, meet our expert team, see our advanced technologies firsthand, and discuss how we can solve your specific manufacturing challenges face-to-face.